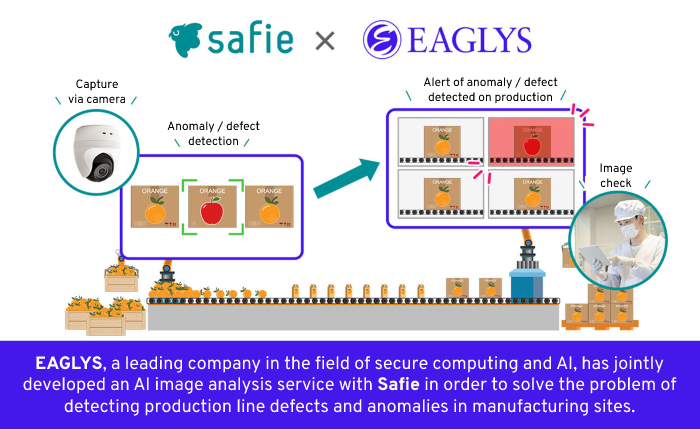

We are pleased to announce that EAGLYS Inc. and Safie Inc., the No. 1 cloud-based video management platform, have begun a collaborative development of an AI image analysis service for detection of defects on production lines at manufacturing sites. By combining EAGLYS’ AI image analysis technology with Safie’s cloud vieo capture services, we have achieved a 91% detection accuracy for anomalous objects at a distance of 24 meters.

Background of the Collaboration Project

In recent years, the manufacturing industry has been facing a shortage of workers, due to the decreasing number of workers in Japan. In the last 20 years the workforce has decresed by approximately 2 million (-11.6%), from 10.02 million in 2002 to 10.63 million in 2019. (1)

On the other hand, in addition to normal production line operations such as processing and assembling products, a large number of man-hours are required for product quality control. Tasks such as visually checking for defects in equipment and contamination by foreign substances add up to the amount of work undertaken by the manufacturing industry as a whole is increasing day by day.

(1) https://www.meti.go.jp/report/whitepaper/mono/2020/honbun_pdf/pdf/gaiyo.pdf

Overview of Joint Development: Easy introduction of high-precision AI image analysis cameras to factories

In collaboration with Safie, which has been contributing to on-site DX and operation improvement with its cloud recording services, we have started to develop an AI image analysis solution that can detect defects and foreign objects on production lines at manufacturing sites with ultra-high speed and high accuracy.

High-precision AI image analysis cameras will not only make it easier to detect abnormalities and foreign objects on production lines at manufacturing plants and distribution centers, but will also make it possible to use footage to verify actions, remotely manage and execute work, and review operations.

Testing Results: Detection of foreign objects at a distance of 24 m with 91% accuracy

During the experiment, we were able to detect a foreign objects and anomalies on the line up to 24 meters away with an accuracy of 91%. This accuracy is difficult to achieve even by visual inspection. Nevertheless, we successfully achieved this high level of precision without affecting the work flow of the machine.

In addition, by adjusting the angle of view and tuning the AI algorithm to suit the process and product, we can expect to achieve a higher level of precision in the detection rate.

Future Development

In addition to the current development and taking into account the results achieved from this demonstration experiment, we will also address other issues and needs that manufacturing plants are facing. We aim to contribute to the productivity improvement at manufacturing sites and help alleviate the pain points of a declining workforce and skills transfer in the manufacturing industry as a whole.

About Safie Inc.

Safie is a cloud-based video management platform which brings our customers a new standard to manage their video assets anytime and anywhere.